PROJECT

HIGHLIGHTS

HEALTHCARE

MOSES H. CONE

MEMORIAL HOSPITAL

Air handling unit (AHU) fan problems can severely impact business- no matter the industry, especially when you factor in the time of year, and size of building. The costs accompanying AHU failure including business downtime can run into the millions. Healthcare facilities are among the industries that would be most affected by a failed system. Fortunately the Moses H. Cone Memorial Hospital in North Carolina, a facility that could have been significantly affected by an AHU failure is relieved today. Moses H. Cone is a 517 bed hospital and children’s emergency center housing administration offices and regional operations offices, for the Cone Health network. When one of the building’s 2 DWDI (double width double inlet) fans serving the building’s AHUs began showing signs of serious trouble, the facility’s chief engineer reached out to Thermal Resource Sales (TRS) Sales Engineer Rick Cates of NC, who partnered with custom air handling manufacturer TMI Climate Solutions for a prompt solution.

12

Custom Fans

10%

More efficient.

65,200

CFM

CHALLENGE

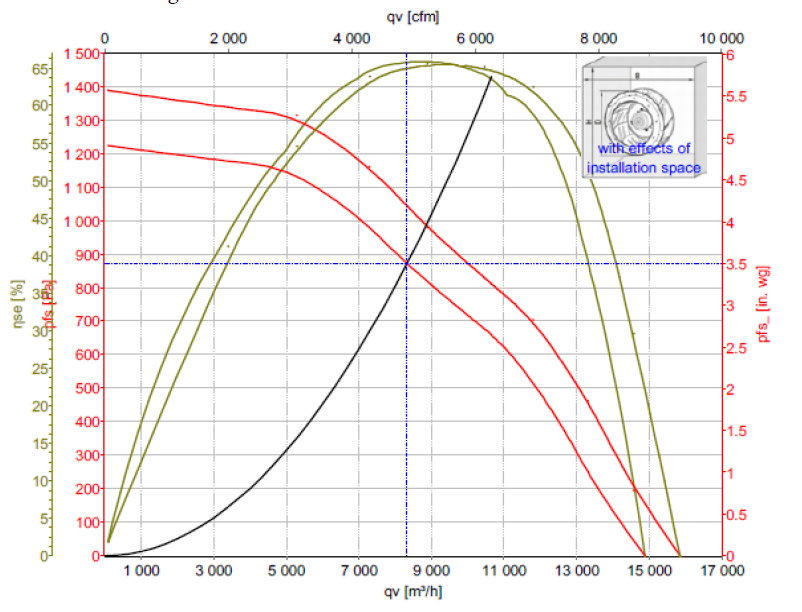

The Hospital needed a quick solution to solve its deteriorating AHU issue. Since just one of the facility’s supply fans for the building’s AHU had begun to fail they needed a rushed solution before it went out completely. DWDI fans are not built for redundancy so, if the one fan had failed, the load on the remaining fan would’ve been too great and the facility would have faced an unbearable winter. In addition to reliable fans with redundancy protection for future maintenance and service; other replacement fan requirements included: Expedited delivery, modularity to easily fit in small footprint, high reliability of at least 38,000 CFM (total) at 4 inches of static pressure per fan replacement. Another critical requirement was quick and easy installation due to one already worsening DWDI fan.

SOLUTION

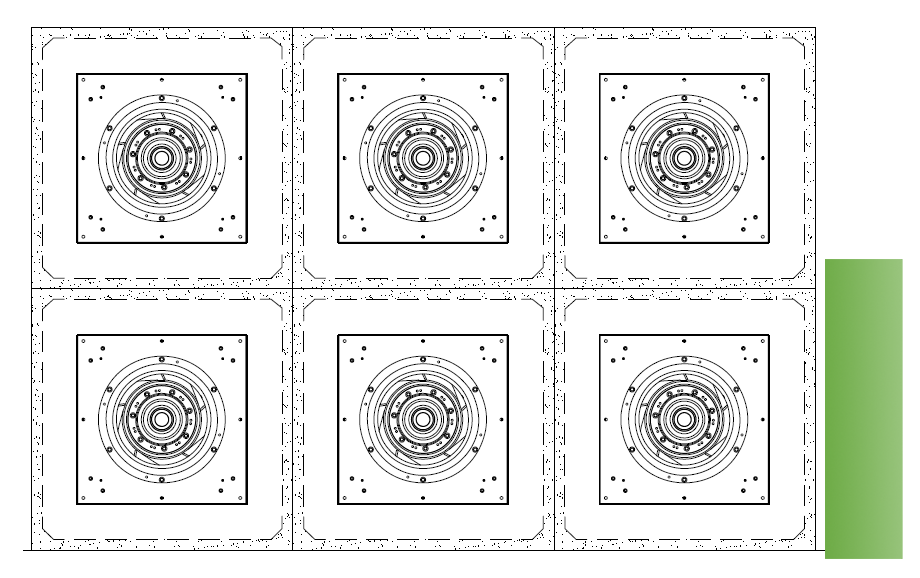

To meet the client’s capacity and energy requirements, as well as provide redundancy, TMI Climate Solutions supplied 2 Custom EC Motor Fan Arrays, manufactured in Galvanized Steel with Acoustic lining for optimal performance and unit efficiency. To reduce sound levels and provide redundancy protection when fan maintenance is required, multiple fans were stacked in an Array. The Arrays were built with an arrangement of 6 fans each. Each Array would provide 35,800 CFM at 4 inches of static pressure, which satisfied the total 65,200 CFM requirement. The modular EC fans run at 1,773 rpm and were designed to replace the operating DWDI fans inside the existing AHUs. TMI received the order on November 28th, and had to ensure that the customer received the first array of 6 fans and installed in less than 2 weeks to transition the failing fan. “The first six fans were rushed and delivered the Tuesday after New Year's Day”, “The old fan was ripped out. Then the new fan array had to be installed.”, “Because of their modular fan cube design, the fans could be carried through the building’s doors and hallways easily, to the Mechanical room for assembly.” With minimal required effort and electrical wiring, the new fans were up and running smoothly by Wednesday morning. And most importantly, the clients considered the installation a great success.

RESULTS

Today the Moses H. Cone Memorial Hospital can continue to operate without fear of having to shut down due to AHU failure. The employees that occupy the building can work without the annoyance of discomfort and noise. And, the new fan arrays satisfied all requests and will provide the facility redundancy protection for the future. The chief engineer estimates that the new fans are 5% to 10% more efficient than the previous DWDI fans and is happy the installation was done ahead of schedule. “They actually had the project connected in two days instead of the three expected —and that included removing the massive old fans,” said WHO. “When you work with TMI, coordination is always excellent.” The installation went exceptionally well due to TMI’s ability to rush deliver the new fans. “No other manufacturer would have been willing to guarantee having the fans built and delivered in two weeks,” said WHO. “This is a testament to TMI’s engineering and manufacturing capabilities and flexibility. In our opinion, TMI is the best solution for anyone looking for a Retrofit solution.”